Toy Designers & Inventors Offer to Help Medical Community in the Fight Against COVID-19

March 23, 2020 │ History has shown us that in times of tragedy, and when people are in dire need of help, humanity will rise to the occasion. Hospitals and medical workers, particularly in the U.S., are sounding the alarm that essential supplies are dwindling amid the coronavirus pandemic, and in response many of the toy industry’s designers and inventors are answering their call.

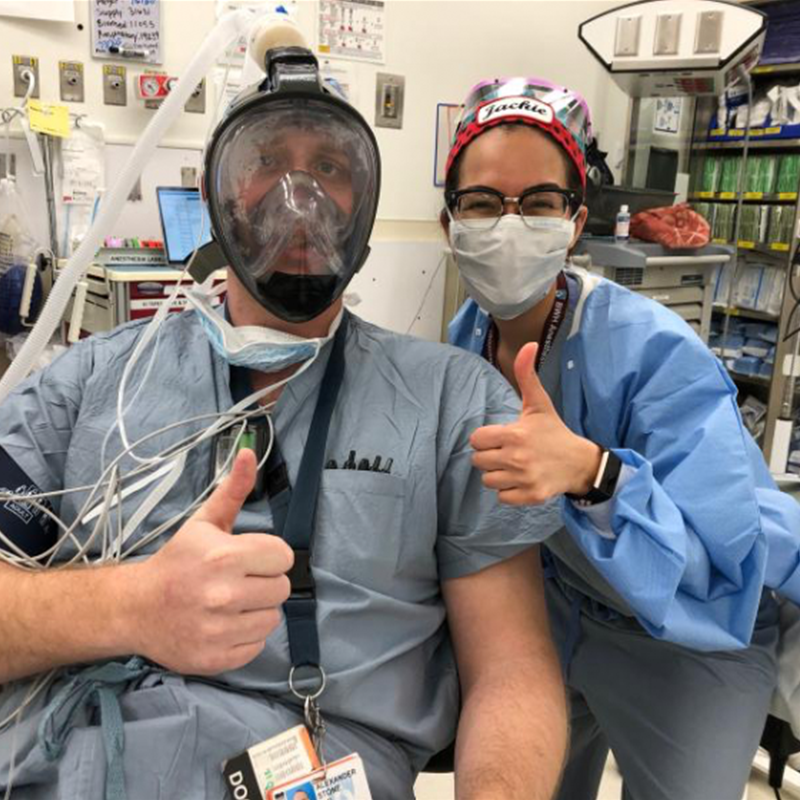

Engineers, designers, and 3D printers in the toy community are banding together to lend their assistance and help tackle the shortage of supplies, which include medical devices and pieces along with essential personal protective equipment (PPE).

“Front line health providers, our last line of defense against the virus, are finding themselves without the critical components they need to keep equipment running, and to keep themselves safe and healthy so they can continue to care for those afflicted,” said Brett Klisch, co-founder of Toy Fair New York's Creative Factor and owner/creative director of Peru Meridian Studios. If all goes according to plan, Klisch will begin 3D printing valves for ventilators out of his Brooklyn studio next week.

For patients, these ventilators have become critical in the care of COVID-19 patient, effectively breathing for someone who can no longer do so on their own. According to a report released by the John Hopkins Center for Security on February 14, there were 160,000 ventilators in the U.S. as of that date.

Klisch added: “When I saw the first news story on the ventilator venturi valves shortage in Italy and how designer Christian Fracassi was able to lend assistance with his 3D printer, I was inspired. It’s been astounding how fast the creative community has stepped up to help.”

Klisch added: “When I saw the first news story on the ventilator venturi valves shortage in Italy and how designer Christian Fracassi was able to lend assistance with his 3D printer, I was inspired. It’s been astounding how fast the creative community has stepped up to help.”

3D printing companies are collaborating with doctors and hospitals around the world to help organize their efforts by developing online databases, open-sourcing design files, and connecting volunteers with hospitals in need. To help facilitate this urgent need, many of the patents on these medical parts and devices are being opened to anyone and no IP lawsuits are being brought forth.

How You Can Help:

- If you have a printer and want to help, below you’ll find links to files and instructions to make numerous critical parts. There are face shields available to print cheap, quick, and easy so that those who have even the most rudimentary of printers can help. Valves for ventilators like those made in Italy are also now needed in other regions and the files have been made available online so they can be printed and sent to hospitals in need.

- For those who have the skills or the hardware to help but don’t know where to offer assistance, the list below, compiled by Klisch, provides resources on different organizations that will direct you where the need is.

If you have the capabilities to design, engineer, or 3D print parts as well as ship them, here are the companies offering to organize your assets and direct them to the right organization in need:

Equipment and Parts Needed

Ventilators & Parts

3D Printed Face Masks

Plastic Shield Masks

Fabric Masks

Requests from the Medical Community

These are open-source calls to actions by hospitals and universities for the community to donate their time and expertise to come up with new solutions.

- CoVent-19 Challenge – an initiative led by anesthesiology residents of Massachusetts General Hospital plans to ask engineers and designers to help develop a new rapidly deployable ventilator and other innovative solutions to the ventilator shortage.

- Code Life Ventilator Challenge – the Montreal General Hospital Foundation, in collaboration with the Research Institute of the McGill University Health Centre, is launching a global innovation challenge, backed by a $200,000 CAD prize, calling for teams to design a simple low-cost, easy-to-manufacture and easy-to-maintain ventilator which could be deployed anywhere needed to save lives. To motivate participation from local manufacturers, the institute encourages participants to submit provisional patents prior to the announcement of final designs, while granting license to local builders to manufacture their designs during the COVID crisis. Participants have until March 31 to submit their design proposal. A jury will select three finalist designs on April 15 and share them to medical professionals worldwide.

- Federation of the Plastics and Composites industry – the organization has issued a call out to 3D printing companies that have production capacity to respond to France’s urgent need for masks and medical equipment for healthcare staff.

Additional contact: Marc Madec, 06 08491064, madec@fed-plasturgie.fr

- Mobility goes Additive – the European Commission has called for printed components (masks and ventilators for respiratory equipment) to be made available.

- John Hopkins University Hospital – the hospital has put a call out for 3D printable parts that are open source and printable for use.

"In times past, our parents and grandparents were called upon to come together to fight different types of war," said Klisch. "Now we are being called to fight a new war, one against an invisible invader that can be stopped by making items of defense, not offense – where we care for and support our frontline defenders and the sick. Together we will get through this!"

To find out more about how you can help or to provide new resources to add to this list, please contact Brett Klisch.